The 2022 Confined Spaces Code of Practice Unpacked

Introduction to the Confined Spaces Code of Practice

Confined spaces pose unique risks and hazards that require careful attention and management to ensure the safety of workers. In December 2022 SafeWork NSW published the Confined Spaces Code of Practice, which serves as a comprehensive guideline to safe working in confined spaces.

This article explores the key features that are important to both WHS professionals and operations managers who may be faced with the dilemma of dealing with a confined space.

Enhanced Definition and Identification of Confined Spaces

One of the significant updates in the 2022 edition is an expanded definition of confined spaces. The code now provides a more detailed explanation, encompassing various characteristics that define such spaces, such as limited access, potentially hazardous atmospheres, and difficulties in evacuation. This clearer definition helps employers and workers better identify and classify confined spaces within their workplace, leading to more effective risk assessments and safety measures.

So what exactly is a confined space?

The code provides improved guidance into what is, and is not, a confined space:

A ‘confined space’ means an enclosed or partially enclosed space that:

- is not designed or intended to be occupied by a person

- is, or is designed or intended to be, at normal atmospheric pressure while any person is in the space; and

- is or is likely to be a risk to health and safety from:

- an atmosphere that does not have a safe oxygen level, or

- contaminants, including airborne gases, vapours and dusts, that may cause injury from fire or explosion, or

- harmful concentrations of any airborne contaminants, or

A confined space is determined by the hazards associated with a set of specific circumstances and not just because work is performed in a small space. Entry into a confined space means a person’s head or upper body is in the confined space or within the boundary of the confined space. (our emphasis)

Confined spaces are commonly found in vats, tanks, pits, pipes, ducts, flues, chimneys, silos, containers, pressure vessels, underground sewers, wet or dry wells, shafts, trenches, tunnels or other similar enclosed or partially enclosed structures, when these examples meet the definition of a confined space in the WHS Regulation.[1]

Improved Risk Assessment and Hazard Control

The 2022 code of practice continues to place great emphasis on the importance of conducting thorough risk assessments before entering any confined space. It provides detailed guidelines on identifying potential hazards, including atmospheric, physical, and biological risks. It also emphasises the need to establish appropriate control measures to mitigate these risks effectively. By following the code’s recommendations, employers can create safer working environments, reducing the likelihood of accidents, injuries, and fatalities.

For example, the code states that trenches are not considered confined spaces on the basis of the risk of structural collapse alone but will be confined spaces if they potentially contain concentrations of airborne contaminants that may cause impairment, loss of consciousness or asphyxiation. (note: trenches are subject to the code of practice on excavations)

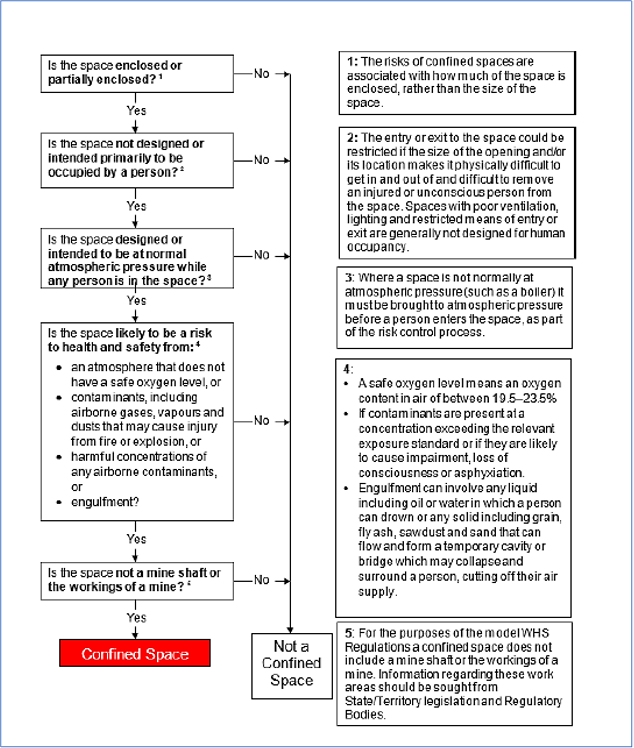

Flowchart for Determining a Confined Space

The code also lists a very practical decision flowchart on whether a structure is likely to be a confined space. It is reproduced here:

Emphasis on Consultation, Competency and Training

Recognising the crucial role of competent workers in confined space operations, the 2022 code places significant emphasis on the employers duty to consult with workers around all aspects of the confined space work, including assuring that they are trained and competent to safely work within confined spaces. Employers are encouraged to provide comprehensive training programs to ensure that their employees have the necessary expertise to handle potential hazards and emergencies effectively.

Enhanced Emergency Planning and Response

The updated code of practice places considerable emphasis on emergency planning and response procedures. It requires employers to develop and implement comprehensive emergency plans, including rescue procedures specific to confined spaces. By adequately preparing for emergencies, organisations can minimise response time, improve rescue operations, and increase the likelihood of successful outcomes in critical situations

Monitoring Atmospheres

Unsafe atmospheres are a significant concern within confined spaces, and the 2022 code emphasises the importance of continuous monitoring and maintenance by a competent person. The level of oxygen and airborne contaminants is a significant contributor to the risk of working in a confined space.

The WHS Regulation contains specific risk control measures for managing these risks, such as:

- the atmosphere of the confined space must have a safe level of oxygen, or if this is not reasonably practicable, any worker carrying out work in a space with an oxygen level less than 19.5 per cent by volume must be provided with air supplied respiratory equipment

- purging or ventilation of any contaminant in the atmosphere of the space must be carried out, so far as is reasonably practicable. The gas mixture used for ventilation or purging must not have an oxygen concentration exceeding 21 per cent by volume, and

- air monitoring must be carried out to determine the airborne concentration of a substance or mixture to which an exposure standard applies if it is not certain on reasonable grounds whether the concentration exceeds the standard or if monitoring is necessary to determine if there is a risk to health.

Work Methods in Confined Spaces

Consideration must be given to whether the proposed work or work process will introduce any new hazards or contribute to the risks of working in the confined space. The WHS Regulation sets out some specific control measures for risks associated with work in confined spaces in certain circumstances:

- ignition sources must not be introduced into a space if there is a possibility of fire or explosion

- while work is being carried out, the concentration of flammable gas, vapour or mist must be less than five per cent of its lower explosive limit (LEL), so far as is reasonably practicable. At LEL of between five per cent and 10 per cent, the worker must be removed unless a gas detector is used, and the worker must be immediately removed if the LEL is equal to or greater than 10 per cent

- risks associated with the introduction of any substance or condition into the space from plant or services connected to the space must be eliminated so far as is reasonably practicable, and

- ensure a person does not enter a confined space to carry out work unless there is a system of work that includes communication with the worker from outside the space and monitoring of conditions within the space by a stand-by person in the vicinity of the space and, if practicable, observing the work being carried out.

Collaboration and Communication

The code emphasises the importance of effective collaboration and communication among all stakeholders involved in confined space operations. Employers are encouraged to establish clear lines of communication, ensuring that relevant information is shared promptly and accurately. This collaborative approach fosters a safety-conscious work environment, where everyone remains informed, aware, and prepared to respond to potential hazards.

Compliance and Enforcement

To ensure adherence to the code, the NSW government has established strict compliance and enforcement measures. Employers who fail to comply with the code’s provisions may face penalties, fines, or legal action. Regular inspections and audits are conducted to assess compliance levels and identify areas for improvement. This proactive approach holds employers accountable for the safety of their workers and contributes to an overall culture of safety within the confined space industry.

Getting Help

Understanding the confined space code of practice and the WHS Regulations in your state or territory can be a daunting task and many business owners are unsure on whether they are compliant with the new Code of Practice. Our advice to any business or worker who thinks that they may be working in a confined space is to carefully read the Code of practice or alternatively seek guidance from an experienced safety consultant. At BWC Safety we have trained and experienced staff who can guide a business through every step of the process. You can contact us on 1300 471 793 or via our email on enquiries@bwcsafety.com.au

[1] SafeWork NSW. Confined Space Code of Practice. 2022. P5

Professional

Company WHS Review

Ensure your organisation isn’t making critical WHS mistakes by getting expert advice before it’s too late.

“Such a culpable culture can exist only when leadership from the Board down are careless in respect of safety. That cannot be allowed”